PECVD Control System

Overview

A local company was looking for an affordable solution to integrate the array of proprietary instruments to operate in a manual as well as automated sequence, and log data in a csv format onto a thumb drive. Arapahoe Controls provided the Engineering, Control Panel hardware, Installation, and Programming.

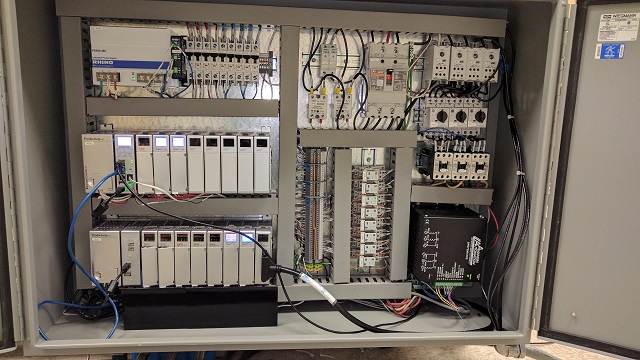

Hardware

Considerations taken into account were

cost, support, reliability, and ease of

use. Automation Direct's Productivity 3000 PLC and C-More HMI were

selected. The PLC interfaces with the following instruments:

Granville Phillips 375 Convectron Gauge.

Granville Phillips 370 Stabil-ion Vacuum Measurement System.

MKS G-Series Mass Flow Controller.

MKS 651C Vacuum Controller.

Seren R301 RF Power Supply.

Twistorr 304 FS Turbo Vacuum Pump Controller.

Leybold D16B Vacuum Pump.

Anaheim Automation DPD72001 Stepper Driver.

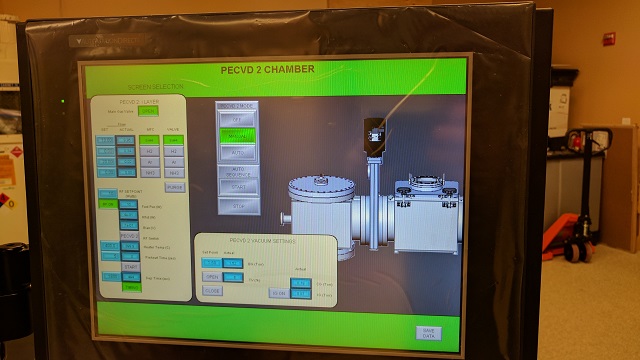

Operation

The operator places the product into the center airlock and seals the access. The gate is opened to the desired chamber, and the operator pushes a button on the HMI to shuttle the product from the airlock to the chamber via a stepper motor. Automation Direct's stepper control module simplified installation and programming.

When the product is in the Vacuum Deposition Chamber, the gate is closed, and the operator inputs parameters on the HMI. The process can be stepped thru manually, or sequenced automatically. The chamber is brought to high vacuum, the substrate is heated, gasses are introduced, and a plasma arc is generated to aid in deposition. After a specified dwell, the process is complete. Data is recorded onto a USB stick in a CSV file for viewing and manipulating in a spreadsheet program. The operator initiates the move back to the airlock for removal.

The Alarm Messaging functions of the HMI are utilized to alert the operator of any sequence failures or out of tolerance parameters.

| ![]()

![]()